1/10/2022 – The TicRing at 85 feet recently quit turning properly. I finally found time to document my findings and pose the question to CQ-Contest.

Physically, the antenna appears to be pointed about 150 degrees. The controller displays 60 degrees. Turn knob CCW to any position beyond 30 degrees and push start, nothing happens. However, with the knob at about 35 degrees and any where CW to 180, a brief tap of START elicites a sharp BUZZ (like an alarm sounder) from the controller. It also appears to rotate the antenna CW; I quickly turn the know CCW to stop rotation, because I don’t want to over-rotate and put coax in a bind.

I don’t see anything in my TicRing manual about an alarm buzzer, nor do I see any resistances for troubleshooting from the ground. I suspect others have encountered this before, and am hoping to get some hints before retrieving the motor from the tower.

I received helpful replies from N4TZ and K3LR

The buzzing you hear from the TIC controller is the relay chattering. That is caused, I think, by holding down the start button (telling the motor to go) while the controller is trying to get the motor to stop turning because it senses that the motor should not run.

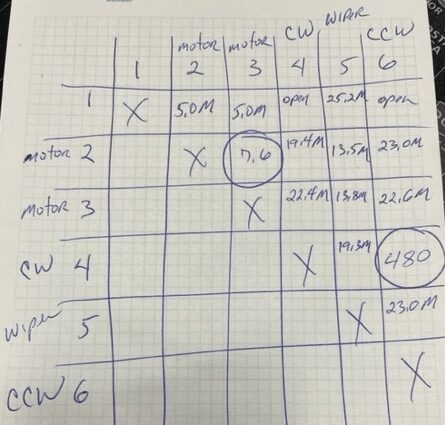

There are five wires to the rotor – two for the motor, three for the direction indicating potentiometer. The motor windings are low resistance, under ten ohms (plus your wire resistance). The direction indication is 500 ohms from the CW to the CCW terminals, with the wiper in between. If the controller does not sense the wiper between the CW and CCW, then it will stop!

It has been known that the pot shaft is sideloaded by the gears such that the wiper will temporarily lose contact. A “fix” is to put some resistance across the controller terminals to make the controller think the rotor is within the range it wants to be and thus the motor will start, moving the pot past the bad spot. In my experience, when the controller had such problems, the needle on the meter would bang to the physical limit, and putting some external resistors would make the meter move back on scale.

The problem with the chattering was, I recall, from the center wiper connection losing contact with the winding. The resistance between the wiper and CW should be minimal when the rotor is turned fully CW (150-180 degrees).

Terry N4TZ

Your report sounds like a POT problem (defective). It is 10 turns and 500 ohms and available at DXE. I suggest you replace the POT and calibrate to zero degrees. With a new pot at the controller you should see 500 ohms across the pot. Zero degrees is when the wiper is at 250 ohms. The ends are 50 and 450 ohms. Only 400 ohms is used to go 360 degrees. You could also have a problem with the gears that drive the pot – make sure you check them.

Tim K3LR

With the advice from N4TZ and K3LR, I’ve ordered a replacement POT from DXE.

1/14/2023 – The package from DXE arrived last evening. This morning in the sub-40 degree temperature, with heavy frost on the entire tower, I climbed up to retrieve the TicRing motor. Before descending, I manually rotated the C-31XR to about 30 degrees, where it would be fine to sit for the NAQP CW contest that started in a few hours, just in case I didn’t get the repair completed and climb back up to reinstall the motor.

On the workbench, disassembly was made easy via the anti-seize compound applied to all the bolts the last time the position pot was replaced. My Weller soldering station makes this work quick and easy – desolder the three wires, remove the pot, install the new pot, ensuring it is set at the center of its 10-turn range, reattach the wires via soldering, and test the motor. Tested perfectly. Back up the tower to reinstall the motor and have the ground crew visually calibrate the antenna, then back to the ground and in the shack to verify calibration.

I sent K5TS, W5LA and KD5YS outside with a walkie-talkie to be my eyes while I handled the control box calibration duties. Got it all finished 45 minutes before the start of NAQP CW.

Hints I’ve learned:

==> Grind a small flat area on the pot shaft so the set screw in the plastic gear will actually prevent the gear from slipping on the shaft